Ok so we've now reached the pictures after the tobacco has come out of aging and is almost ready to be rolled. They bring the humidity up in a special room once the bales are broken down and then once again sort the tobacco even further.

Here you can see the racks where the tobacco is placed after each bale is broken down. The racks are rolled into rooms where they slowly increase the humidity.

Once the humidity is brought to between 70% and 75%, the tobacco is brought out to be sorted once again, this time being prepped for each individual blend.

Once the tobacco is sorted, it goes to a room where it is broken down by blend and weighed to exact blend standards. A specific number of leaves go into each blend and this process ensures that each is correct.

Once the blend weights are separated properly, they bag the blends into 1 bag. This 1 bag contains enough tobacco to create 50 cigars and the bags are packed into boxes to be stored until they are ready for use.

This is the rolling floor at the factory. It holds 100 pairs and they only roll Davidoff and Winston Churchill here. The Avo, Zino, Griffin and other brands are rolled at a factory next door.

A bunching machine being used by the 1st half of the pair. He has the recipe bags delivered to him where he can separate the tobacco for his/her ease of use. The ring gauge is judged by how the bunch feels in your hand.

A roller stretching the wrapper leaf and finishing the cap on a cigar. It is amazing to watch how fast yet delicate they are.

This is where the supervisors weigh the cigars to ensure they will draw. Davidoff does not use draw machines, they judge by weight. If the cigar is too heavy, they will cut the cap, test it themselves, and if the draw is good, they will send it back to the roller. The roller will remove the wrapper and put a new wrapper and cap on. If the draw is too tight, they break the cigar in half and throw it away.

And the last pic in this series is a little surprise!

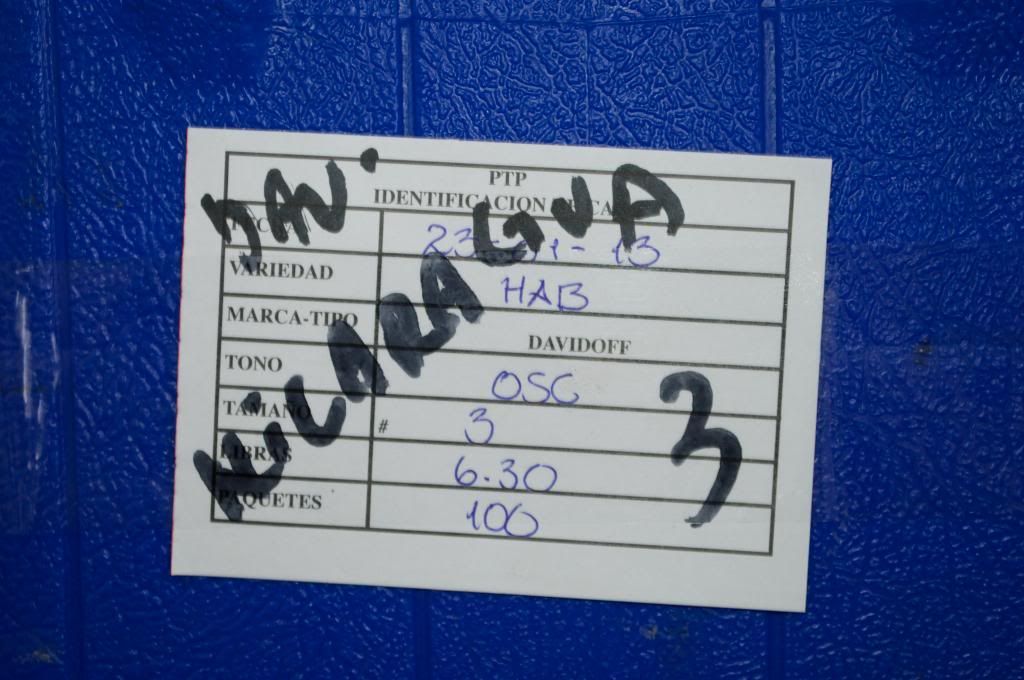

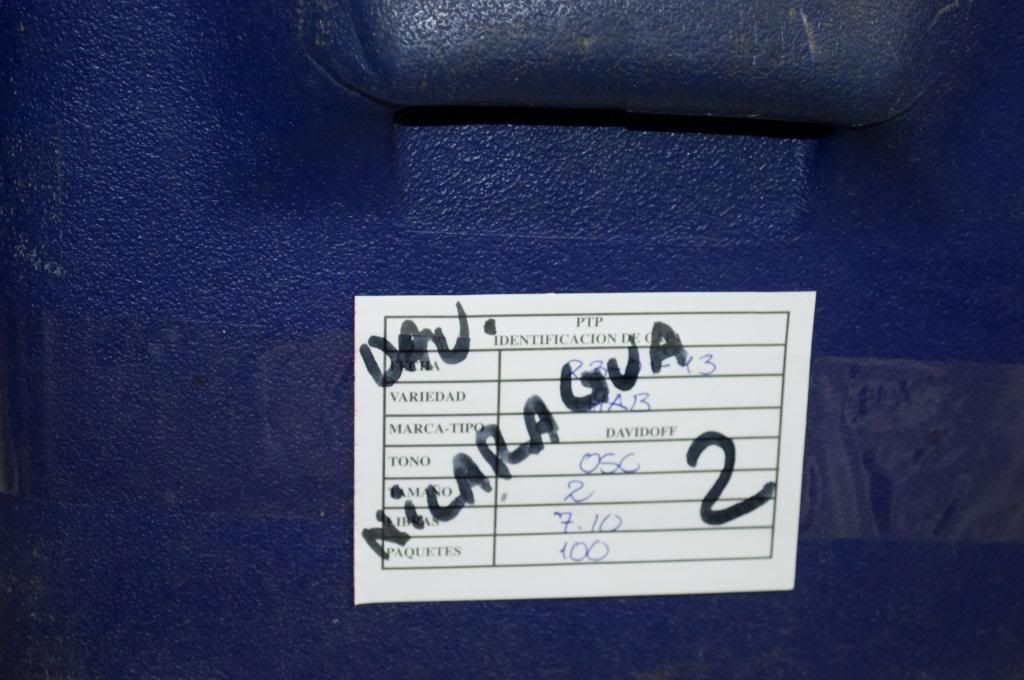

They use coolers to store tobacco between when it is brought out of aging and sorted for blends. As you can see, these coolers are marked Dav. Nicaraguan! Yes, Davidoff is working on a Nicaraguan blend. Details were minimal other than confirming this is indeed a new cigar to be released sometime in the future, no date was provided for release however. It may be a couple of years even before we see them. I saw no rollers working on them nor any crates with finished versions.